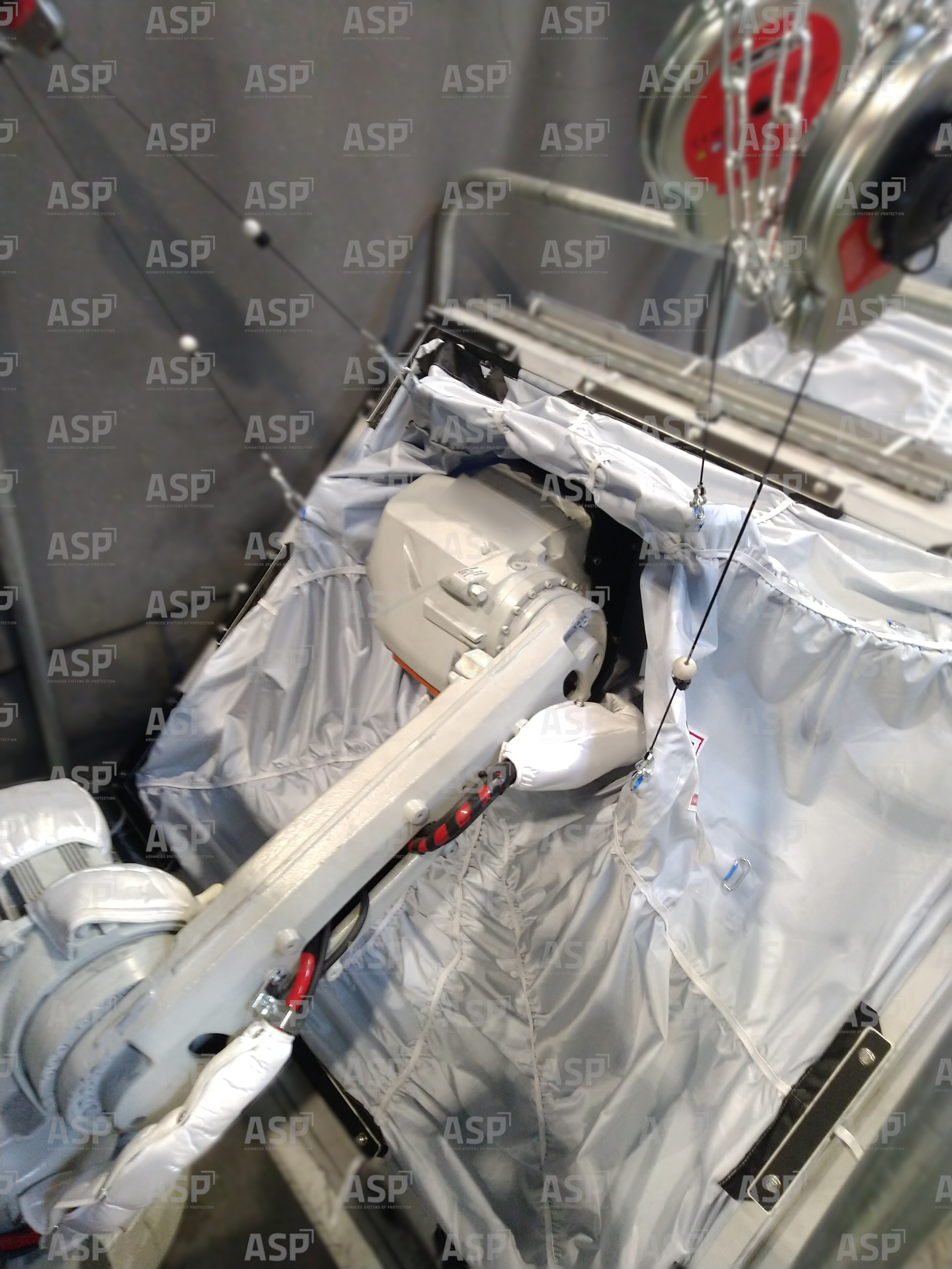

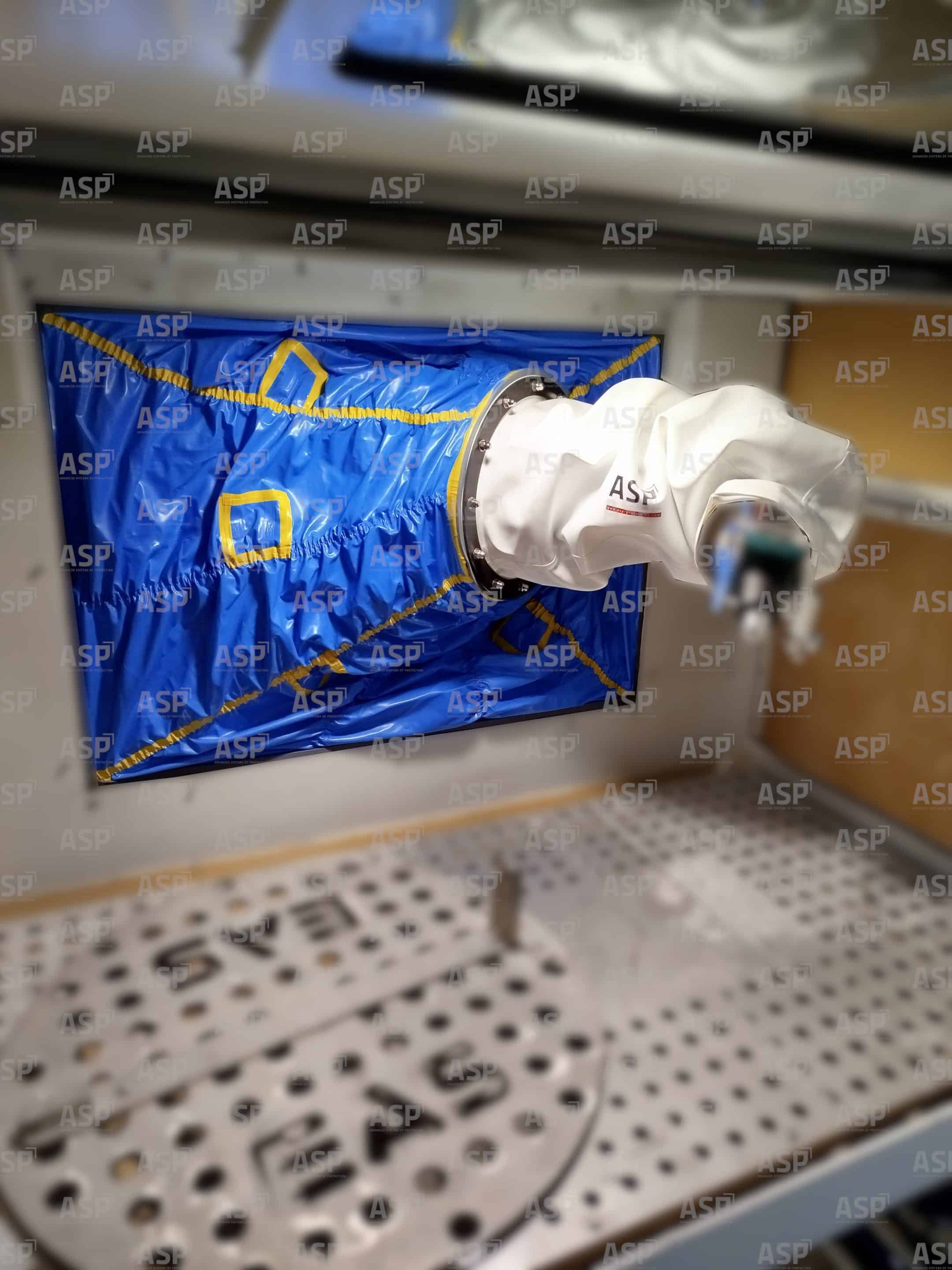

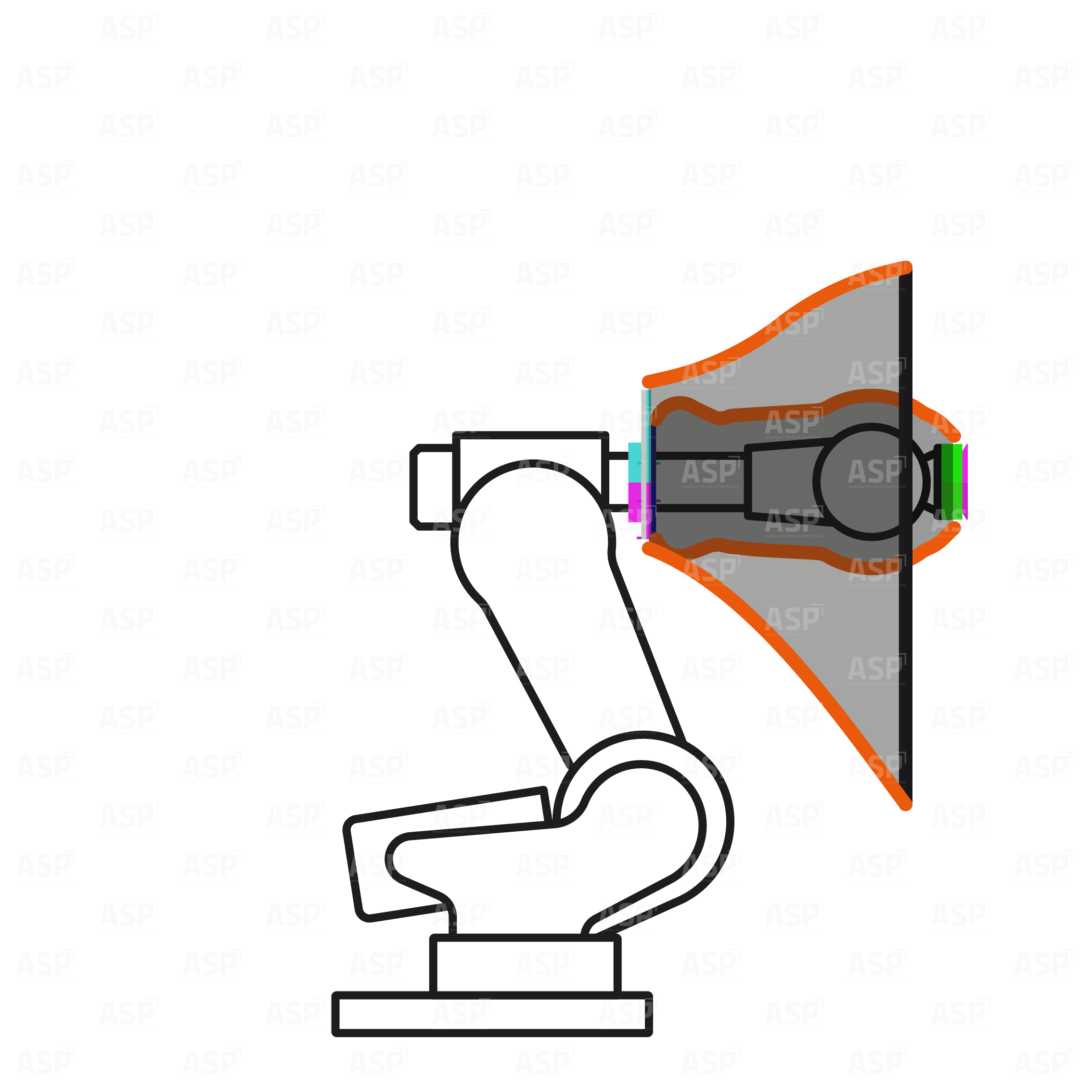

ASP specialists determine the diagonals corresponding to all robot cycle movements, then design and manufacture the FST cover, which can be adapted on-site.

ASP window covers effectively resist lubricant splashes, abrasive chips, and high-pressure sprays, providing efficient insulation for the robot mechanics.