The protective cover for robots in thermal chambers must withstand extreme conditions, i.e. temperatures ranging from -40°C to +90°C, and also be exposed to high humidity variations.

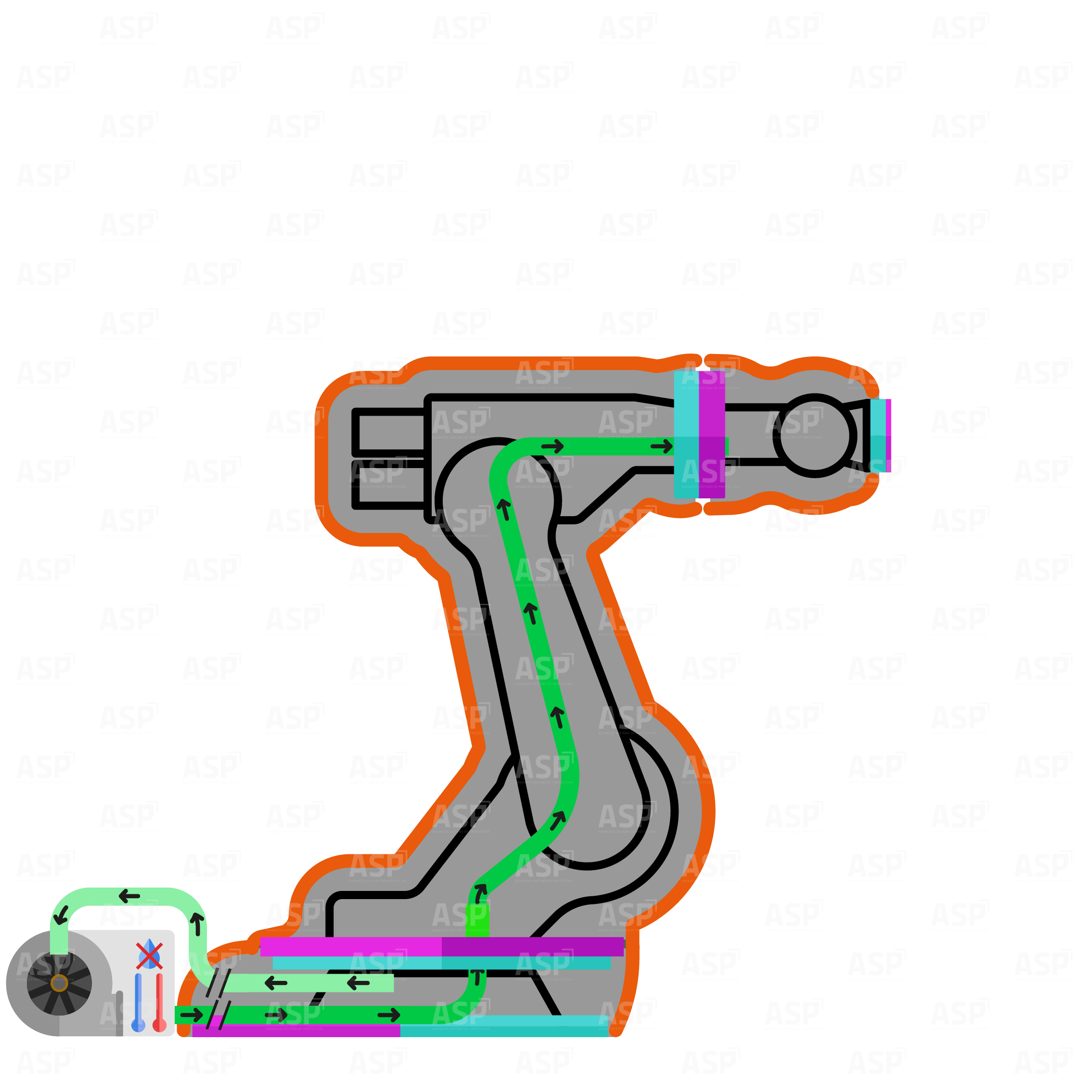

If a robot is used without protection in a cabin with more or less extreme temperatures, it will not be operational. The protective cover heats, cools or dries the air between the cover and the surface of the robot, as required, so that the robot can work in optimum conditions without sustaining any damage. Therefore, continuous ventilation of the robot is necessary and must be taken into account when manufacturing robot covers for use in climatic chambers.

The robot covers in climatic chambers must provide complete protection as humidity must be avoided at all times. This could damage the robot and cause it to freeze or rust. Another particular challenge in this field is the unlimited freedom of movement of the robots in temperature chambers: a problem solved by the custom-made aspect of ASP covers, which are designed according to the robots’ movements.

As a manufacturer of protective covers for robots for all brands such as KUKA, FANUC, ABB, Yaskawa, Kawasaki, etc., ASP offers covers made from different types of fabrics throughout Europe, so there is an ideal protection for every application.

Articulated arm robots or 6-axis robots are often used in the automotive industry, whether in the production of parts or in climatic chambers.

In the automotive sector, individual parts must be tested in climatic chambers, which can simulate any climate. For example, the consoles can be opened and closed by the robot, individual parts or zones can be tested at extreme negative and high temperatures to systematically detect quality defects before production.

These tests can only be carried out if the universal robot or articulated arm robot is protected from the cold or heat by a robot cover. In the automotive industry, a protective cover for robots in thermal chambers is therefore essential.