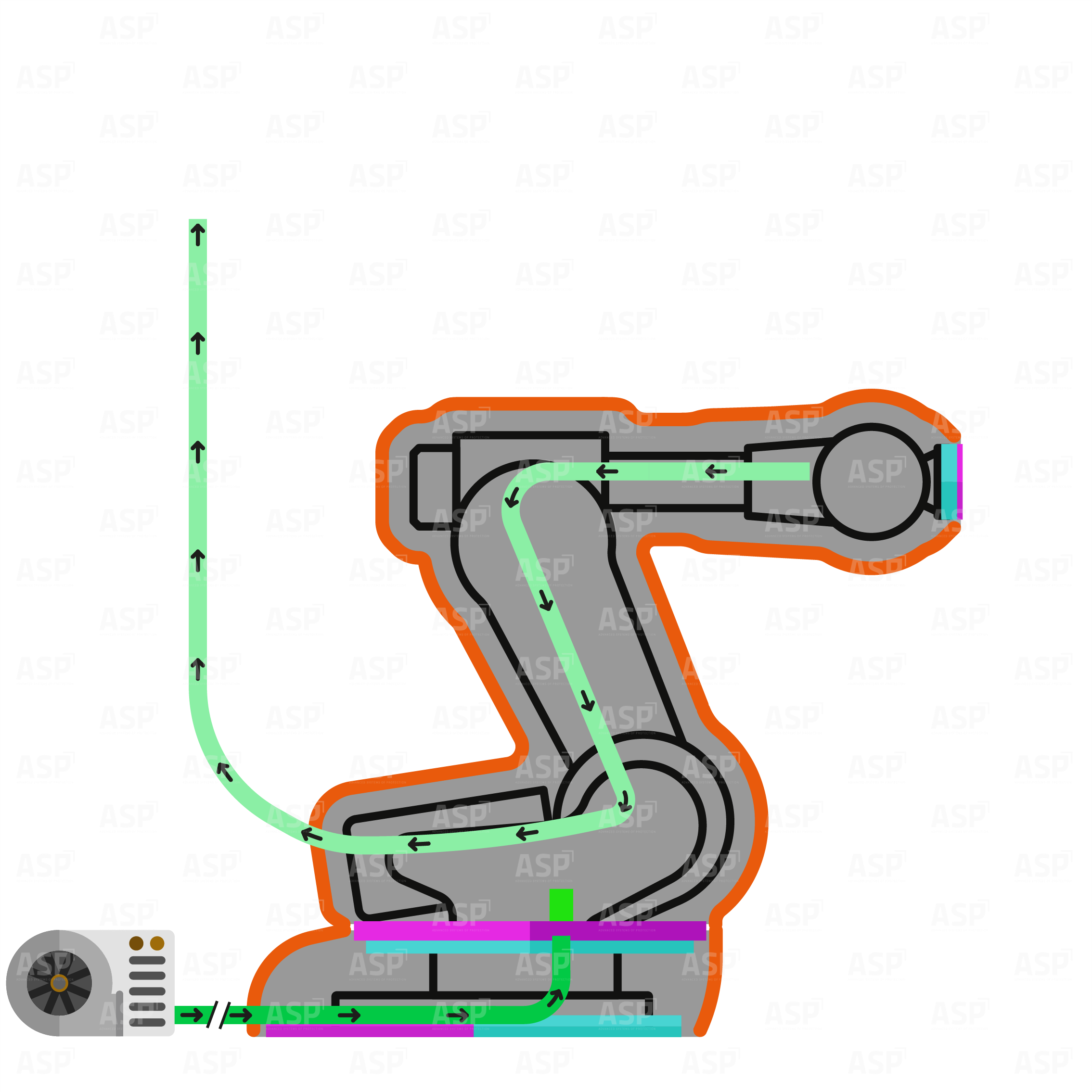

During paint stripping in the automotive industry, robots are used to clean paint strips on the skids used to convey vehicles. Different robot manufacturers offer models suitable for this use, such as KUKA KR 150 or KR 210, ABB irb 6650, YASKAWA/MOTOMAN MH50, FANUC R-2000i-165R. ASP manufactures protective covers for all types and brands of robots.

The stripping process is a major challenge for robots, as high cleaning pressure is used, mainly with deionized or demineralized water, as well as with aggressive chemicals. High-quality waterproof seams on the cover are particularly important in this industrial field to prevent water, dirt, or aggressive particles from getting inside the robot.

Thanks to its experience in the field of robot protection since 1988, ASP has the expertise to develop and manufacture high-quality and high-performance protective covers for surface treatment robots. In these applications, robots must be protected against aggressive chemicals and abrasive processes such as high-pressure deionized water jets. Fluids must not penetrate the robot joints. Otherwise, premature wear or damage will occur.

To extend the lifespan of the protective covers, ASP has developed a repair service. After analysis, damaged covers can be repaired in our factory and reused in production, thereby saving you time and money.