ASP’s protective covers for the food industry, such as in cheese factories and slaughterhouses, comply with European regulations. Made of double-coated fabric with a PE base non-woven fabric, ASP’s range of covers for the food industry resist cleaning products, disinfectants, and high-pressure cleaning.

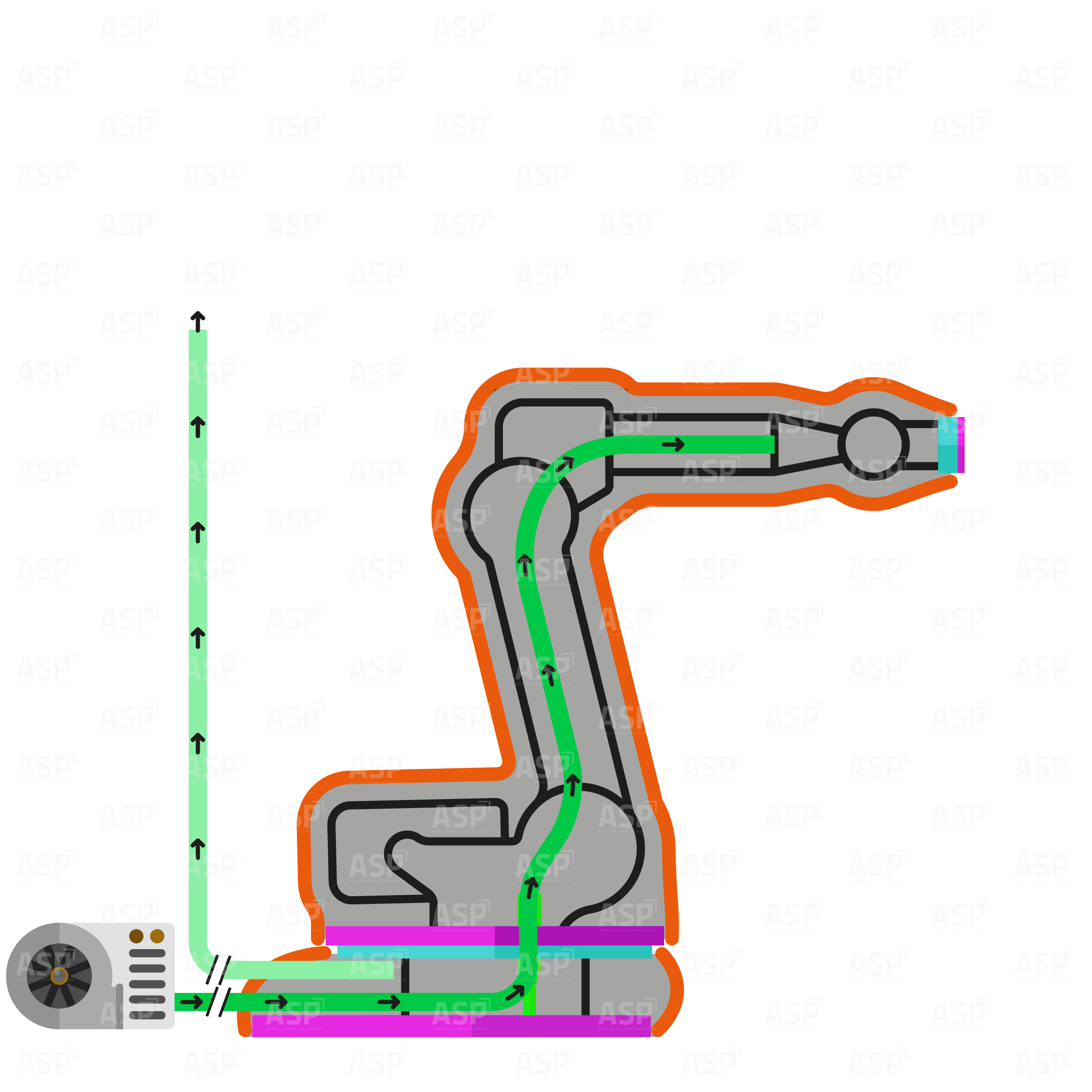

ASP designs, develops, and manufactures high-quality custom robot covers that are suitable for all major robot brands (KUKA, FANUC, ABB, Yaskawa, Kawasaki, etc.) and protect machines in different environments and industries.

The covers are also designed for ventilation and can be inflated from the inside, so there are no folds where dirt or bacteria can settle.