Custom Protection for Your Specific Equipment

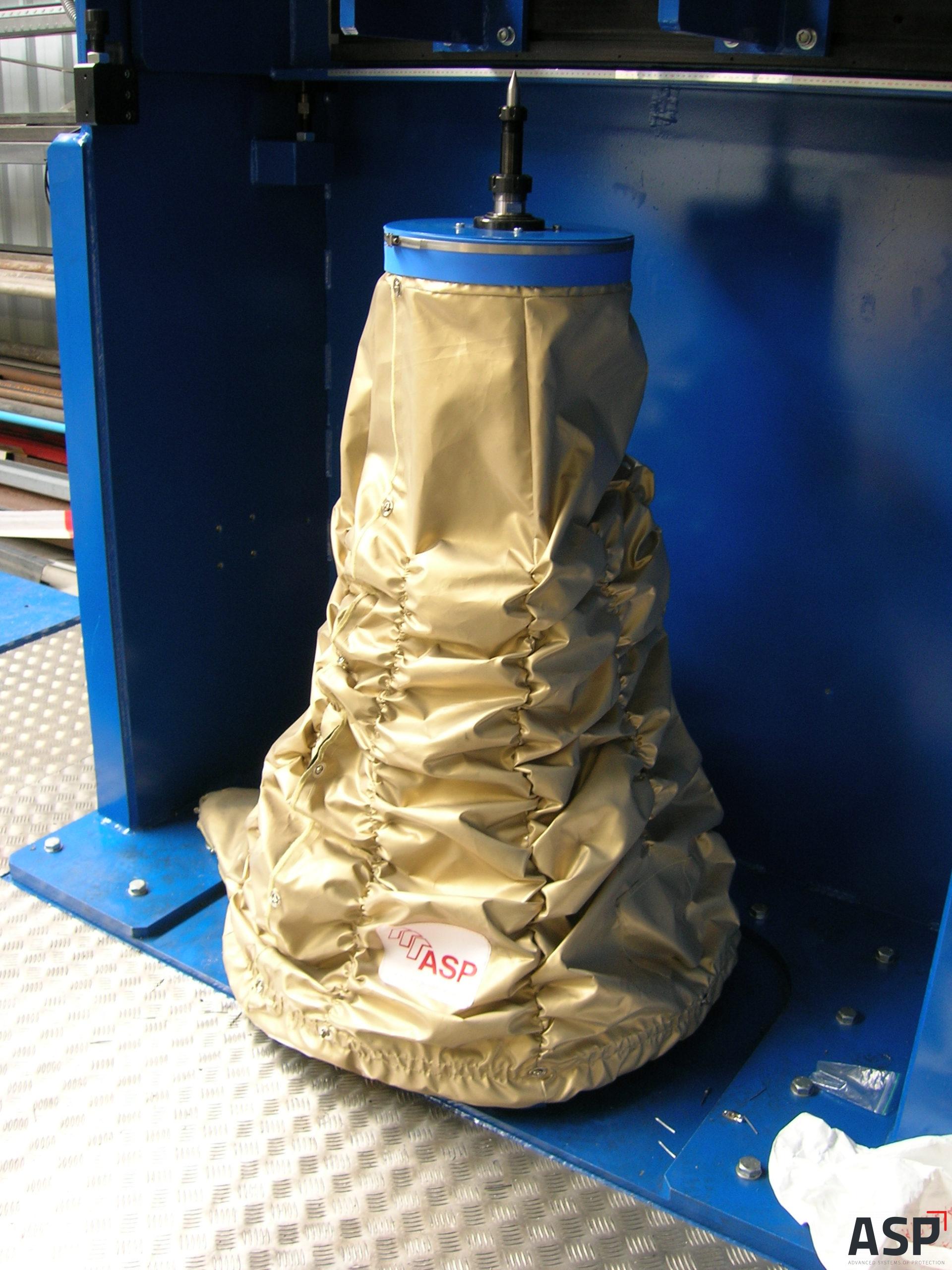

With over 35 years of experience, ASP puts its expertise at the service of protecting a wide range of industrial equipment, far beyond robots. Thanks to our know-how and design office, we develop technical covers and protective solutions tailored to the needs of each sector, taking into account operating constraints and demanding environments.

To create a custom protection solution, we need some information about your equipment: type of device, mechanical constraints, exposure to heat, humidity, chemicals, or dust. This information allows us to select the most suitable materials and design an effective and durable solution.

Our protective solutions cover a wide range of applications:

- Exoskeletons: covers adapted to complex shapes and movements, ensuring hygiene, durability, and safety.

- Vehicles: privacy covers or partial protections for prototypes, testing, and transport phases.

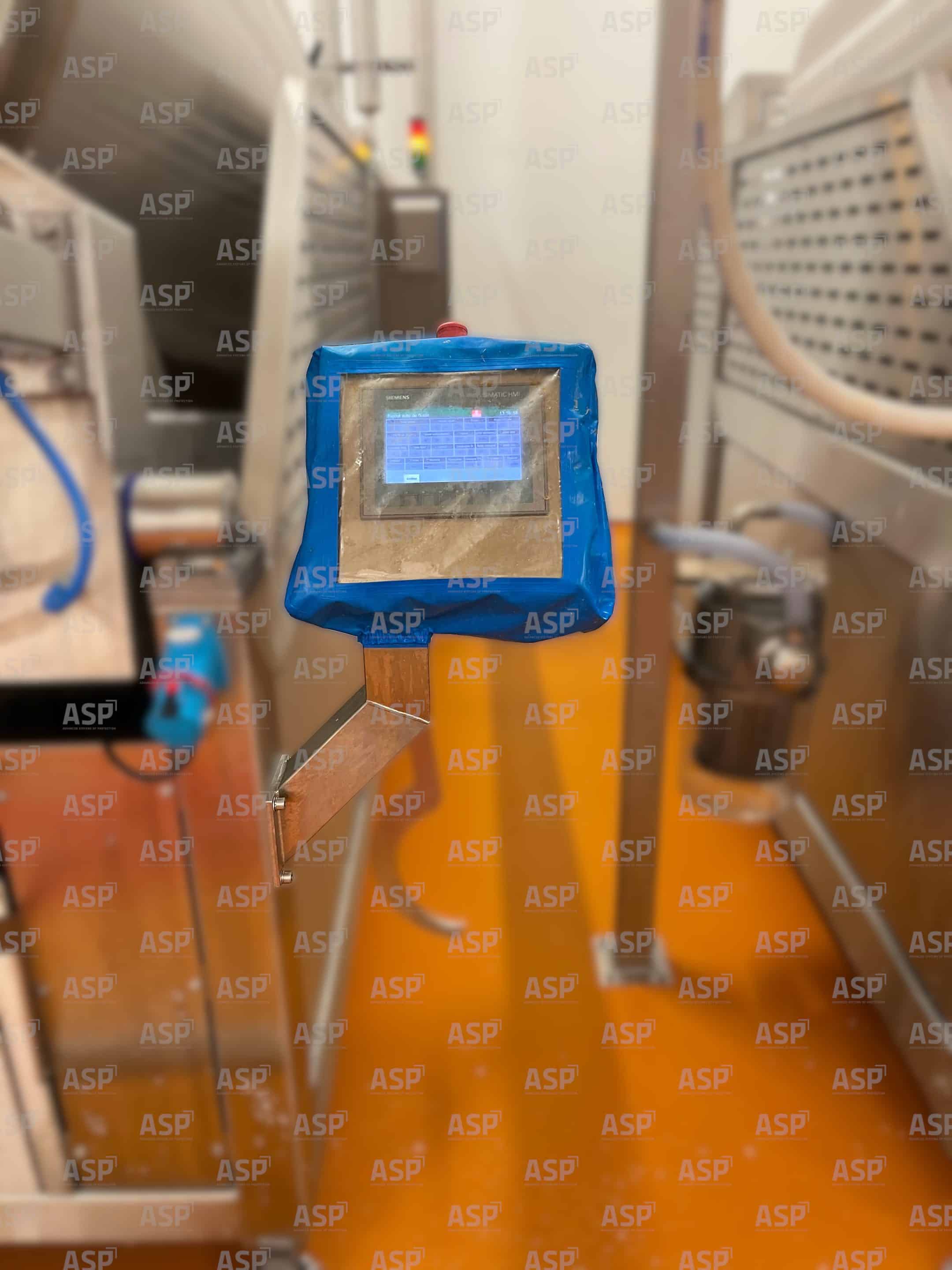

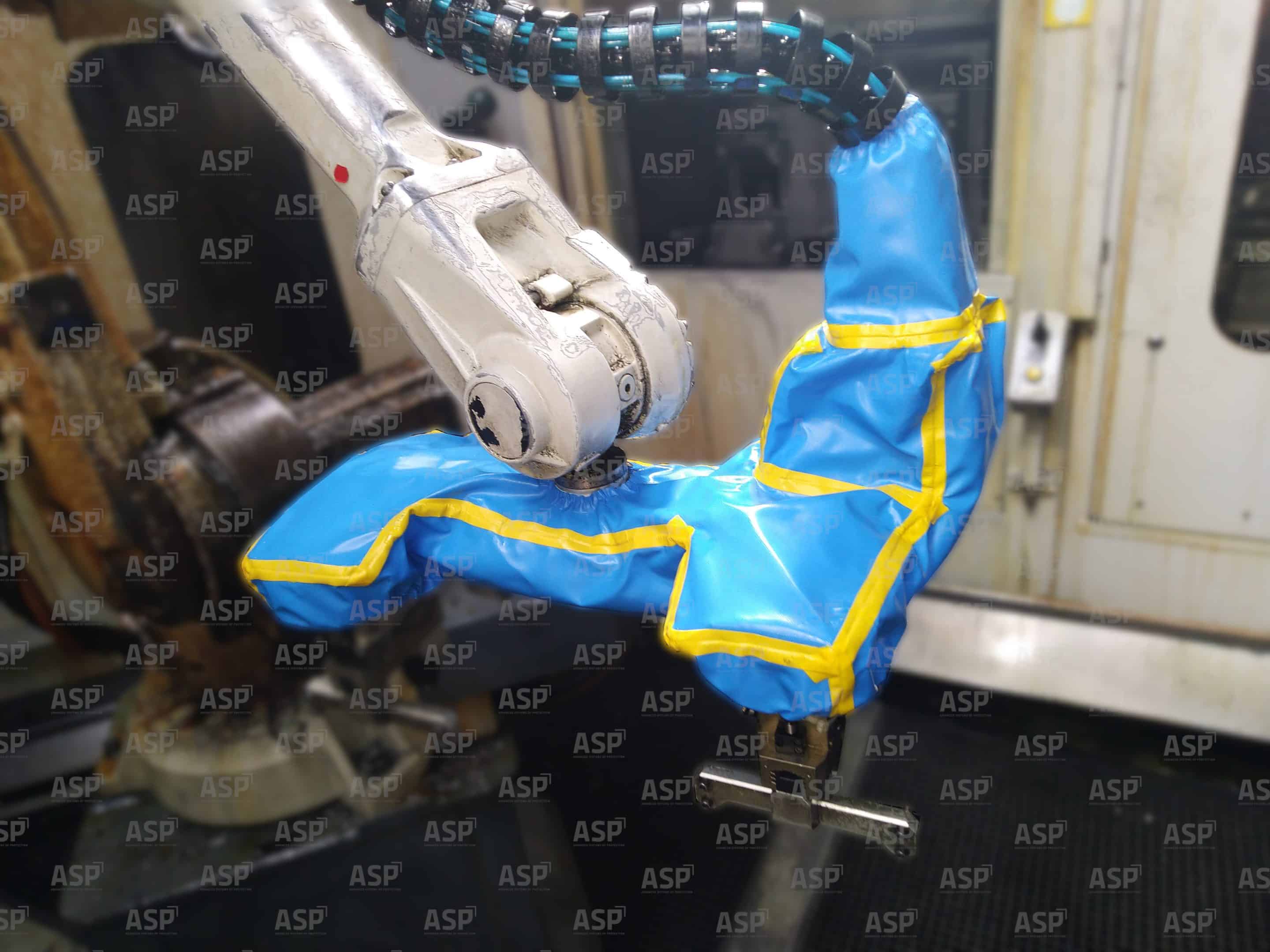

- Industrial peripherals: teach pendants, hoses, grippers, engraving heads … protected from wear and external hazards.

- Measuring devices: covers for scales and control panels, ideal for food industry environments exposed to heavy splashing.

If your equipment is exposed to challenging conditions (heat, splashes, abrasion, chemicals …), our R&D team will support you in developing the most effective solution, perfectly tailored to your use.

Whatever your need, contact ASP: we will work with you to find the best solution to protect your equipment long-term.