Protective covers for robots are commonly used in refrigerated environments in the food industry, such as ice cream factories or food storage facilities, where robot protection is particularly important due to exposure to temperatures that are unsuitable for their working environment. The protective robot cover meets the cleanliness standards required in the food industry.

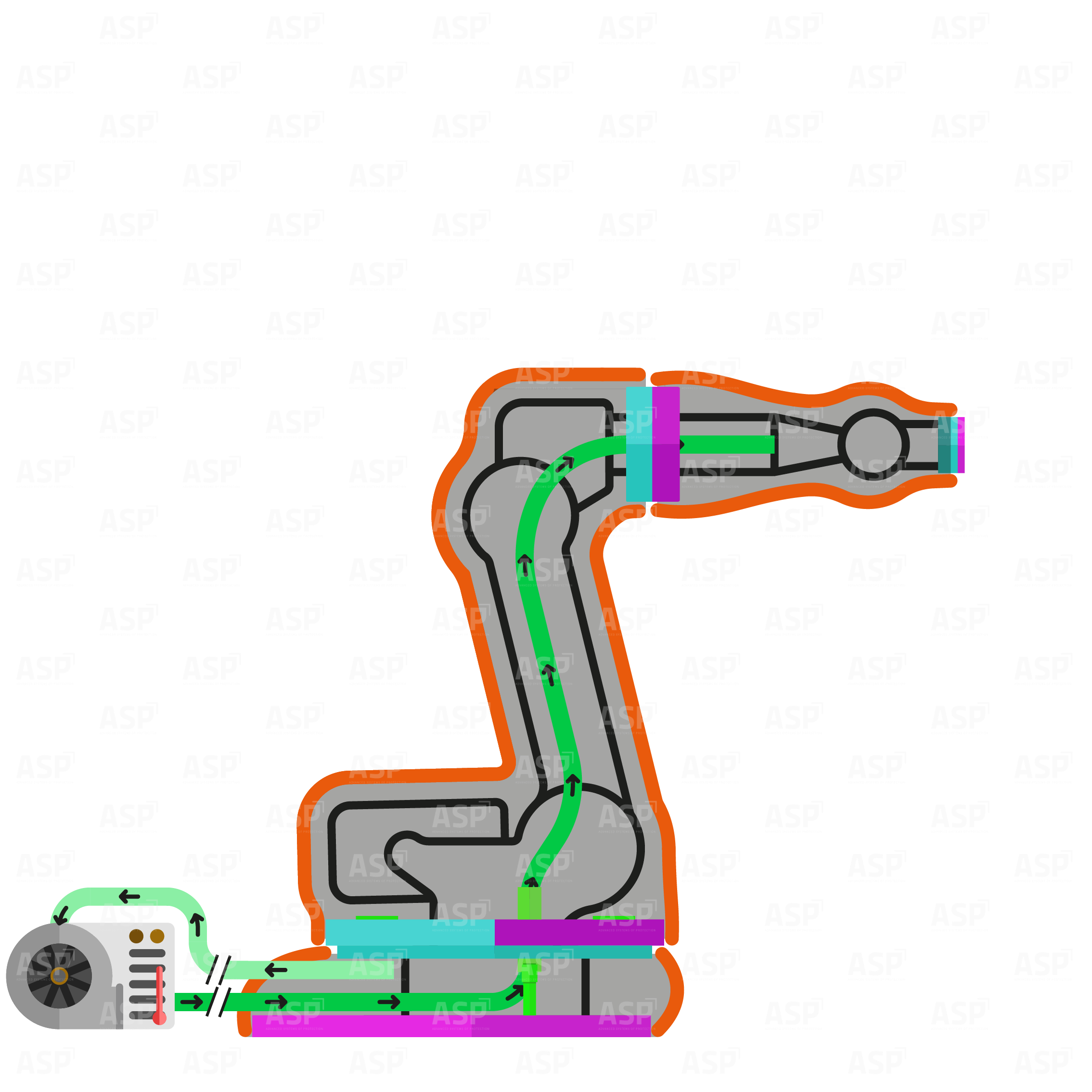

Due to the sub-zero temperatures that can go down as low as -20°C in a cold chamber, ASP suggests using a thermal battery to maintain an acceptable temperature level under the robot’s protective cover. In general, the lower operating limit for a robot is +5°C.

Our protective covers for robots (articulated robots, palletizing robots, 6-axis robots, etc.) in cold chambers prevent bacteria from adhering and are resistant to common cleaning products. The covers are also designed for ventilation and can be inflated from the inside, preventing the formation of folds where dirt particles or bacteria could accumulate. Overall, a robot protection cover offers numerous advantages.