The use of protective covers for robots during polishing, machining, and drilling helps to prevent costly repairs and reduce maintenance costs.

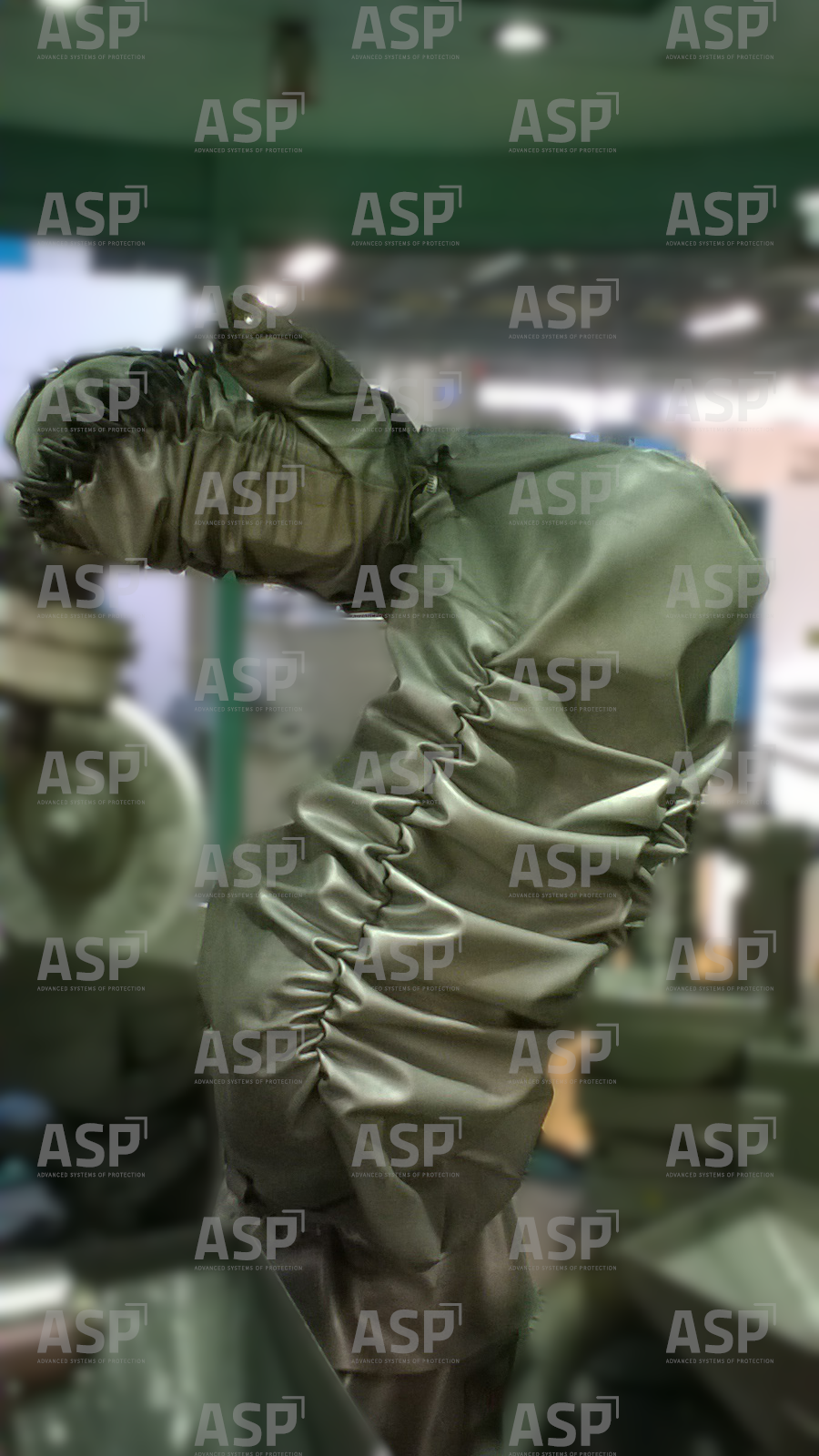

In industrial applications, polishing robots handle, for example, trim parts, and 6-axis robots from brands like KUKA and YASKAWA are used for this purpose. Since polish dust is particularly fine, the robot protection needs to be especially tight. During polishing processes, moisture can also be generated, which is why ASP’s protective covers for polishing also satisfy these requirements.

Thanks to our protective robot covers with welded seams, no moisture can penetrate.

In addition to KUKA and YASKAWA, other brands such as FANUC, STÄUBLI, or ABB are also used for robotic polishing. We also manufacture protective covers for robot models from these manufacturers, such as:

- KUKA models KR 16, KR 60, KR 150

- YASKAWA MH 24

- ABB IRB 4400

- UR 10 (used for small parts)

When it comes to performing polishing operations, it is essential that the cover used is highly elastic and capable of following the axis movements quickly and precisely. Additionally, it must be impermeable to the smallest particles.

To ensure fast cycles and direction changes during polishing work, the robot must be adequately protected. This protection aims to prevent generally abrasive substances such as polishing compounds and chips from entering the robot’s joints and causing damage to the gears.

With decades of expertise, ASP has already developed covers suitable for most types of robots used in polishing applications. ASP also offers specific materials such as Telupro 22, Tortop B+, or TSB 13. Depending on the robot type and substances used, we can provide a custom cover with specific cutouts to match the robot’s movements.

ASP is here to assist you in developing a customized robotic protection solution that precisely meets the requirements of your application.