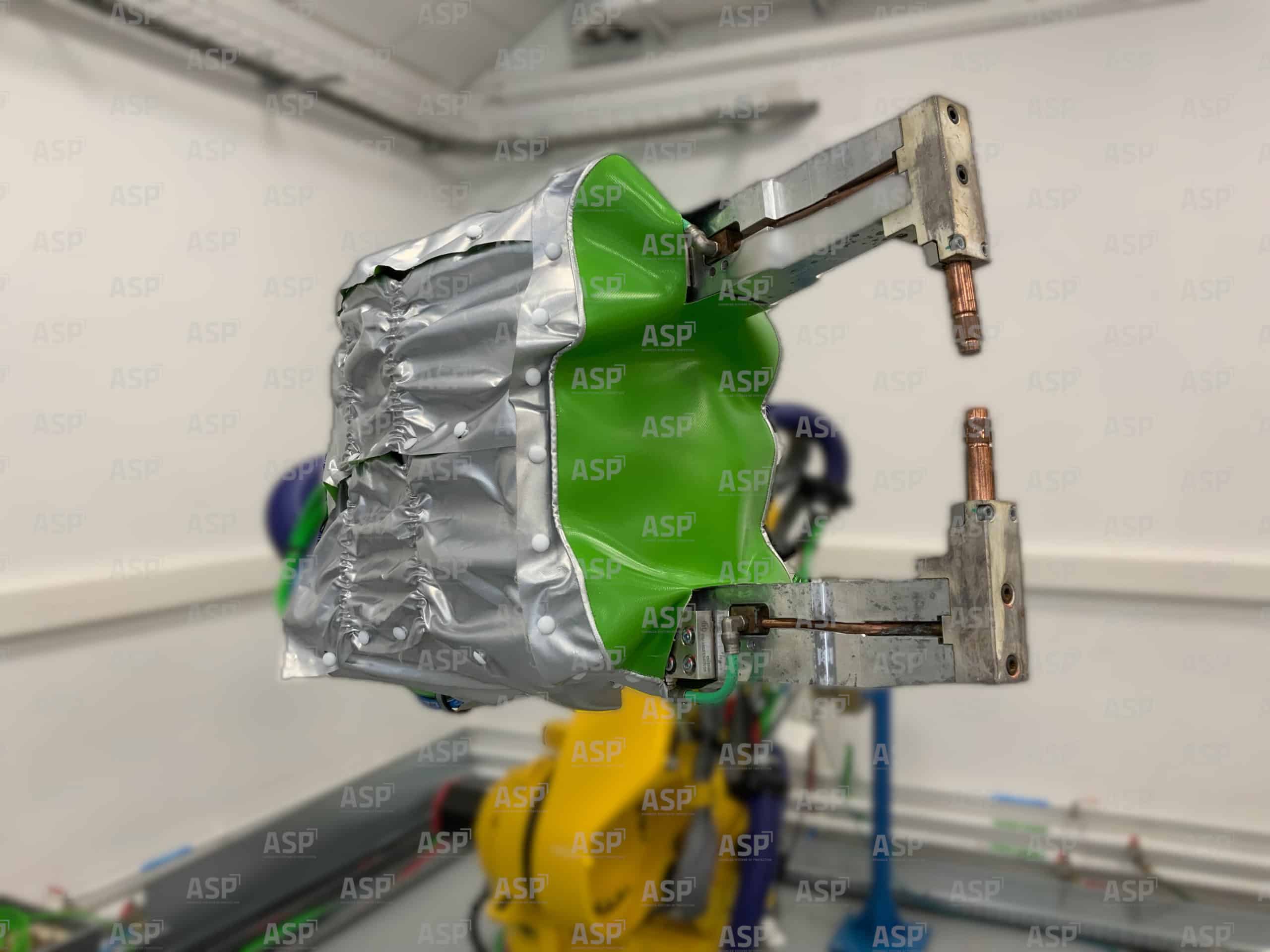

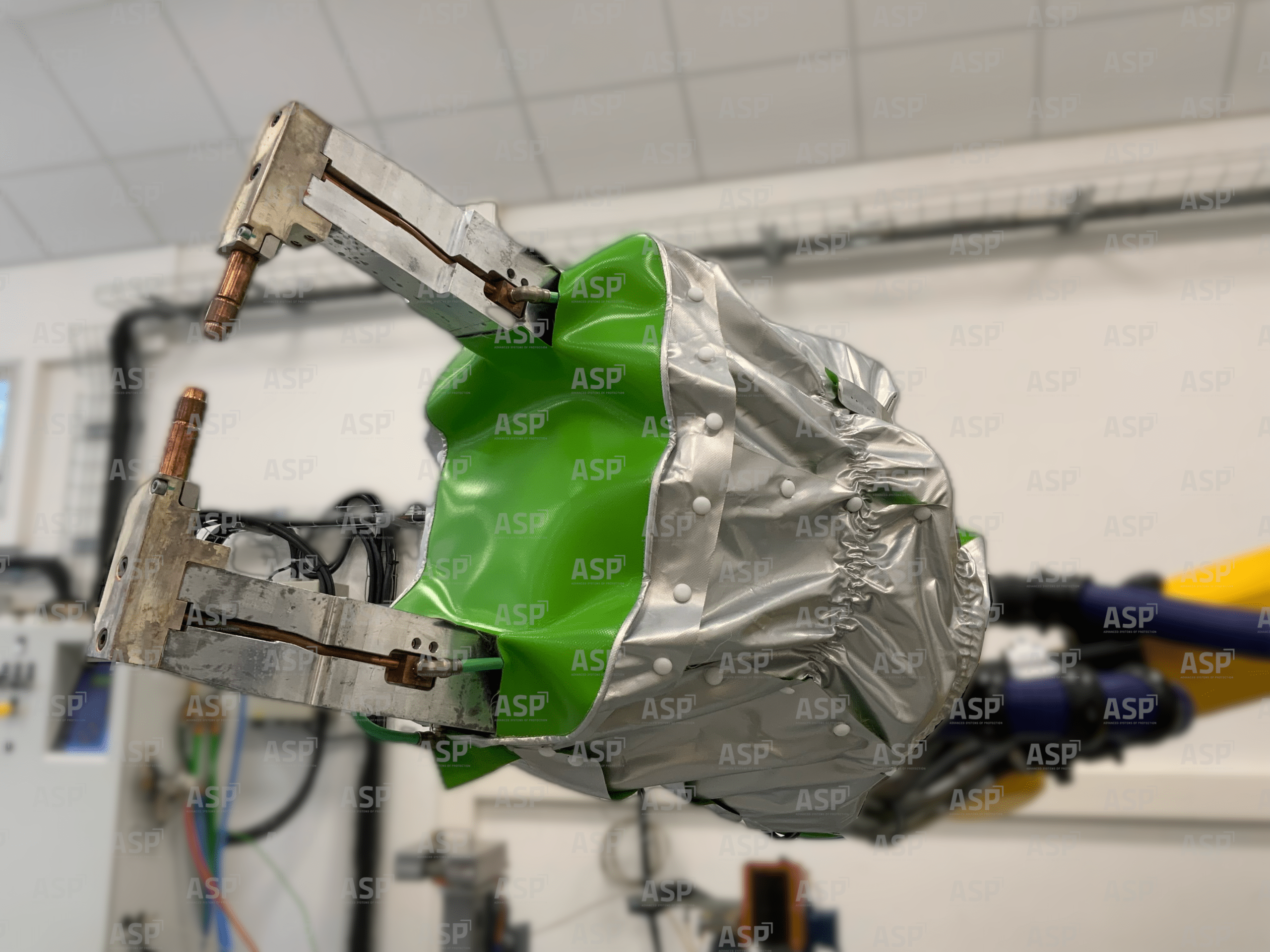

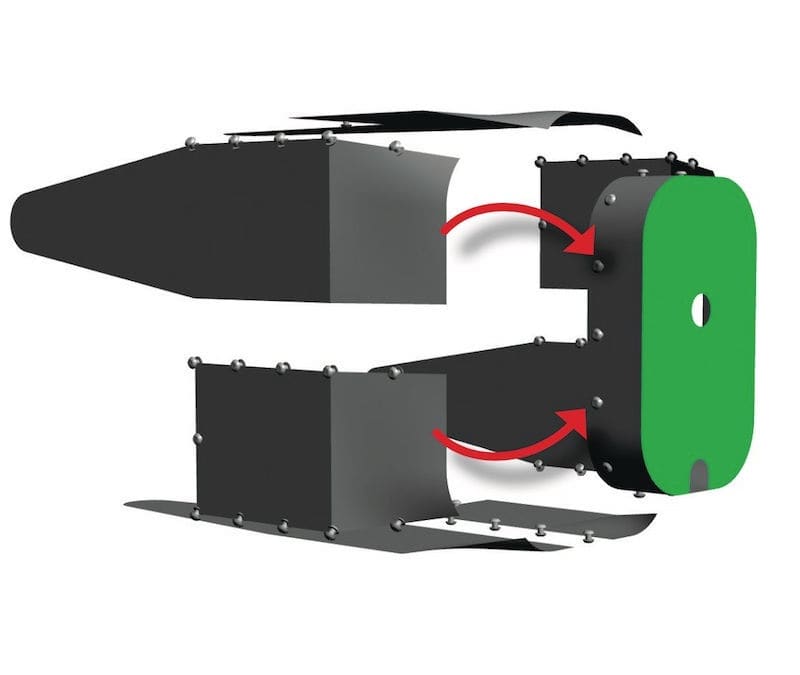

Since 2016, ASP has supplied the CMC range for the protection of welding grippers in the automotive industry. The solution is patented, which means that CMC covers fit perfectly onto different ARO, FTS, DURING, OBARA, COMAU gripper shapes. The one-piece cover concept reduces fitting and removal times during maintenance operations.

For all types of grippers, ASP offers its adaptable cover solution as a replacement for casings. Flexibility, limited size, mechanical resistance, the TREXALIS and CARDEL gripper covers provide optimal protection for your equipment.

When welding car bodies or doors in the automotive industry, for example, it is important to protect not only the mobile welding robots but also the environment. Indeed, sparks that occur during welding can get lodged in the joints on the robots that feed parts on the line, block and soil the harnesses, and damage the robot surface.

Therefore, protective covers for robots in this field not only have great flexibility for sufficient freedom of movement, they are also particularly resistant, flame-retardant, silicone-free, and halogen-free.

The diversity and variety of welding processes have required the development of specific products. The technical fabrics used have special coatings that combine flexibility and resistance to weld spatter. Their aramid bases guarantee excellent mechanical resistance. Whether it’s arc welding, spot welding, laser welding, etc.… There is an ASP protection cover perfectly adapted to each process.