In the aerospace industry, our protective robot covers are notably used in surface treatment processes such as grit blasting and sandblasting, which are highly aggressive environments. Various blasting agents are used in these processes, and the industrial robot needs to be protected either within a blast cabinet or by using a protective window cover.

Sandblasting and Shotblasting Robot Cover

Surface Treatment

Solution description

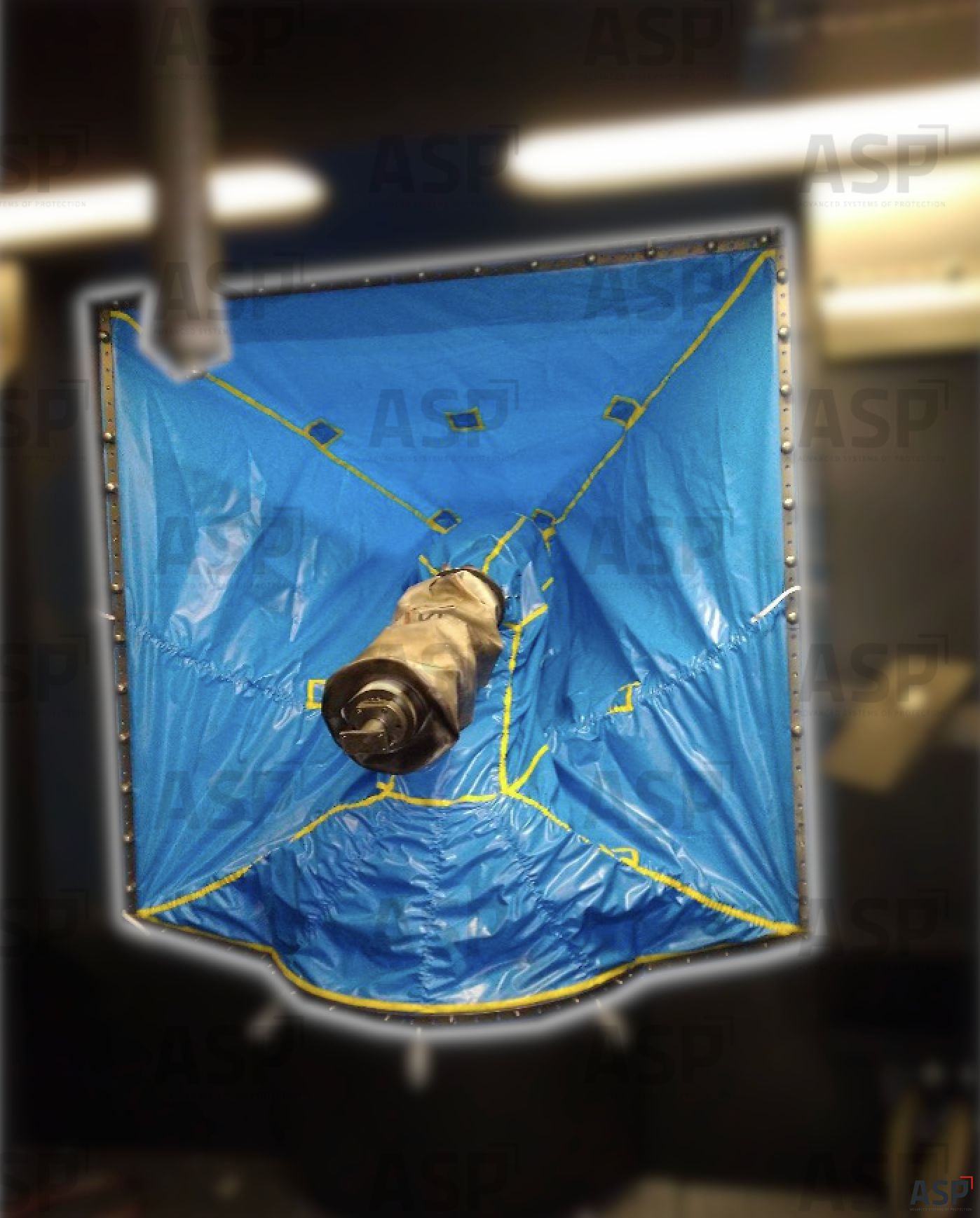

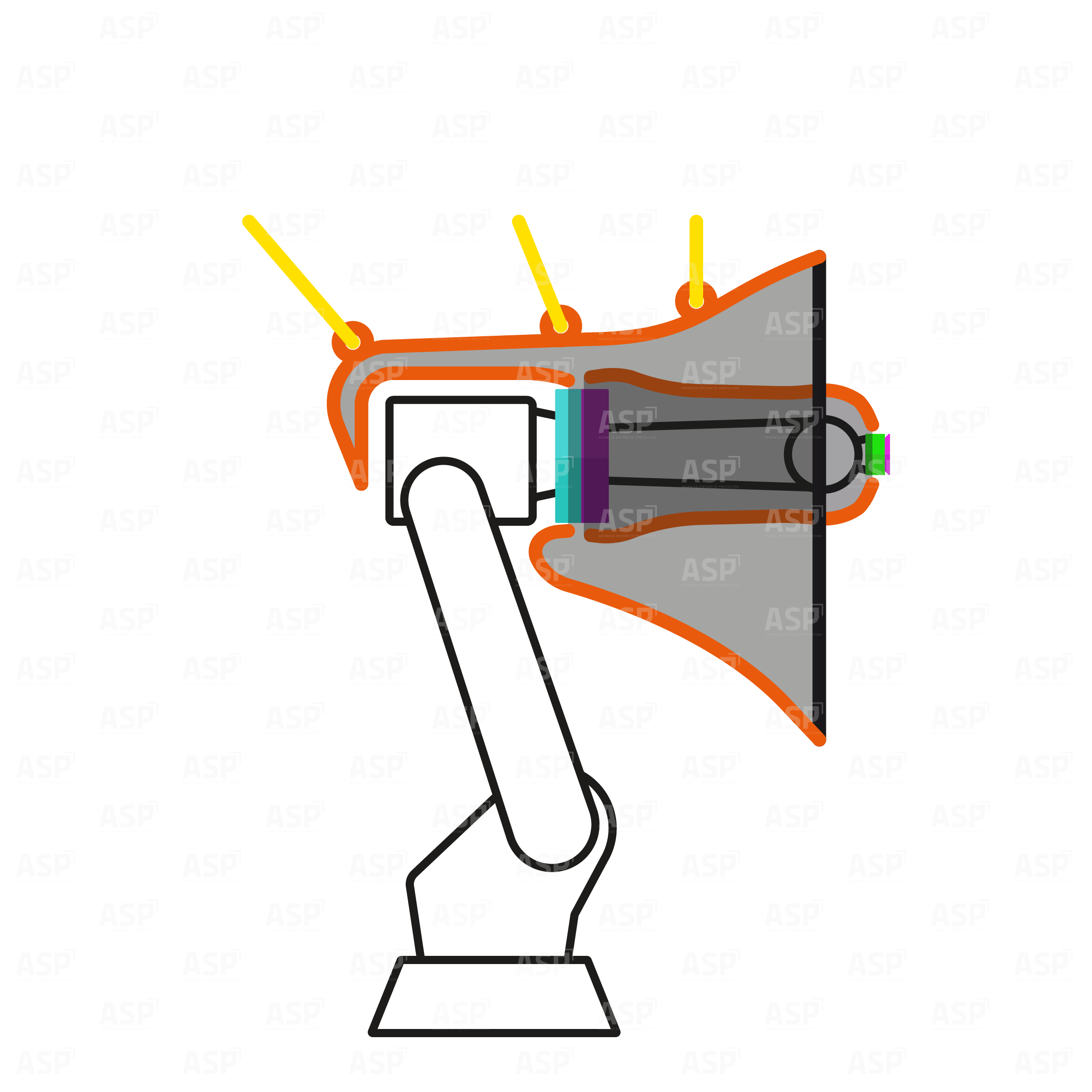

Solution 44: Window cover + wrist joint cover

Interessed by our covers ?

Download the technical sheet

The advantages of ASP

- Customized robot protection covers tailored to your needs: Depending on the jet speed and granulometry, the covers can be made of different fabrics (TORCAL B+ or T1A polyamide fabric).

- The covers provide reliable protection against various surface treatment agents: steel shot, sandblasting, glass beads, steel beads, ceramic beads, etc.

- High flexibility and abrasion resistance for effective robot protection.

- Our protective robot covers are made with welded seams to prevent sand or water penetration, which also meant they are waterproof.

- Sealed rotating joints on different axes for enhanced seal.

- Balancers installed to keep the cover in position during the robot cycle.

- The covers are washable and repairable.

- Specially designed and integrated metal parts on the robot’s surface to provide protection and freedom of rotation for axes 6 and 4.

Your constraints:

- Specific to shotblasting, sandblasting cabins, and window robots.

- Assembly by cold vulcanization or heat welding.

- Excellent abrasion resistance for ventilated and pressurized covers.

- Limited space.

- Infiltration of sand or shot into the robot’s mechanics.

- Complex trajectories.

- High exposure of the robot wrist joint to counter jets.