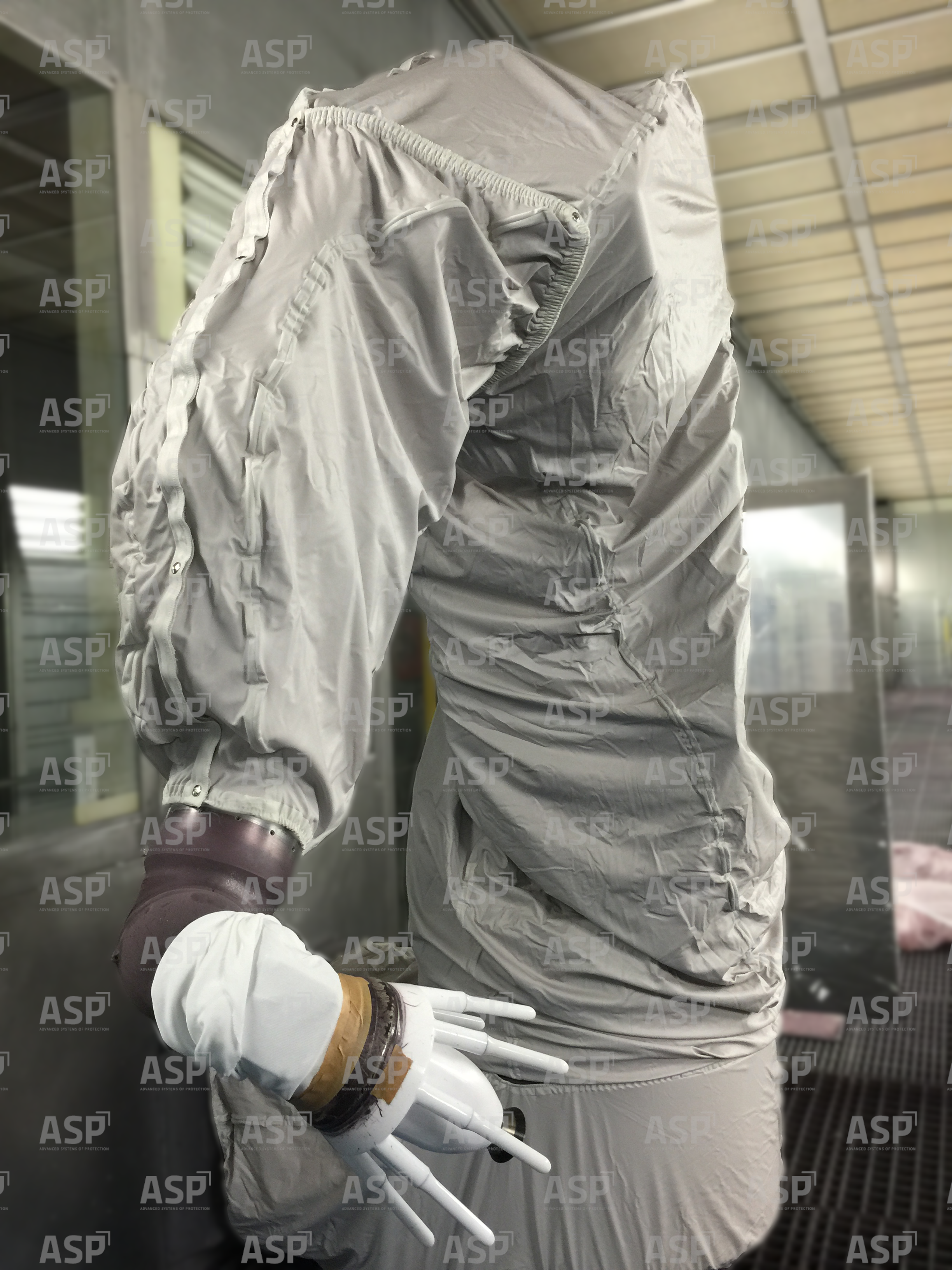

The washable protective covers used in paint, varnish, and plastic filler workshops protect robots from paint and varnish mists, plastic filler beads, and highly demanding environments that can be detrimental to robot mechanics.

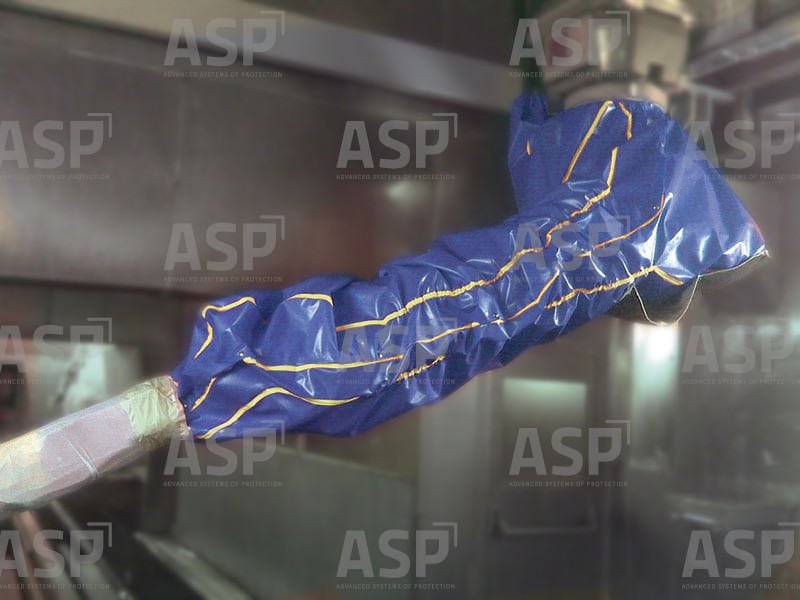

These protective robot covers are used to reduce dirt buildup and wear on the robot’s joints, thus preserving their functionality and minimizing maintenance requirements. ASP paint covers also ensure that no robot fluids or grease are deposited in the process or on the treated parts (vehicles or parts). These covers are specifically designed for paint robots, manipulator robots, and opening robots, providing complete protection from the base to the Axis 4 arm, where the robot wrist joint is often bi-conical. These covers, made of TELUPRO 22, TORTOP B+, and TORCAL B+, have a lifespan of several years and can be washed with industrial solvents.