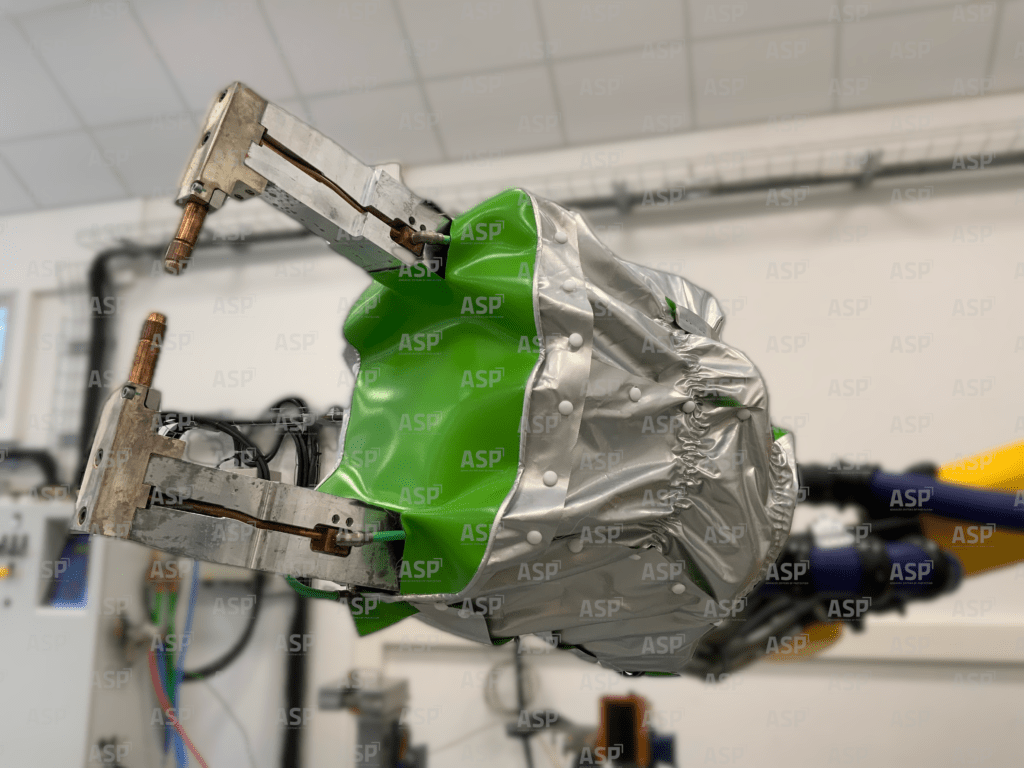

In the welding industry, clamps are exposed to extreme conditions: high temperatures, metal splatter, and wear. To ensure their longevity and efficiency, ASP offers specially designed CMC protective covers to shield every type of welding clamp. Thanks to their custom design, these covers provide optimal protection while reducing maintenance costs.

Tailored Protection for Welding Clamps

Since 2016, ASP has been providing CMC covers for the protection of welding clamps in the automotive body assembly sector. These patented covers are designed to fit ARO, FTS, OBARA, DURING, and COMAU clamps, offering a simple and quick solution for installation and removal during maintenance operations.

Technical Materials and Resistance

CMC covers are made with technical materials offering exceptional resistance to metal splatter and heat. They are also flame-retardant, silicone-free, and halogen-free, making them perfectly suited to demanding environments. Their aramid base ensures high mechanical strength.

Integrated Shield and Flexibility

The covers are equipped with an integrated shield that protects the face exposed to metal splatter. Their design also allows great flexibility, ensuring freedom of movement for the clamp while providing reinforced protection.

Reduced Maintenance Costs

Thanks to their easy upkeep, CMC covers help reduce maintenance costs. They can be easily wiped clean, thus reducing the time spent cleaning clamps and welding robots.

Customized Solution for Your Needs

ASP offers custom protective covers tailored to each welding application. For more information, contact us to find the ideal protective solution for your equipment.