To prevent robot and production line breakdowns, as well as the associated unexpected costs, it is often essential to protect robots in the metallurgy sector. ASP collaborates with you on-site to analyze the type of stresses your robot is exposed to, recommend suitable fabric, and design the appropriate robotic protection solution. With our experienced team of technical designers and state-of-the-art production methods, we provide long-term protection for your robot, even in highly contaminating environments involving chips, oils, chemicals, heat, or water. Our ASP protective covers are also highly effective against welding spatter and sparks. Each protective cover is custom-designed to meet the specific requirements of your robotic application.

Cover for machining robots

Machine servicing, Finishing, Foundry

Solution description

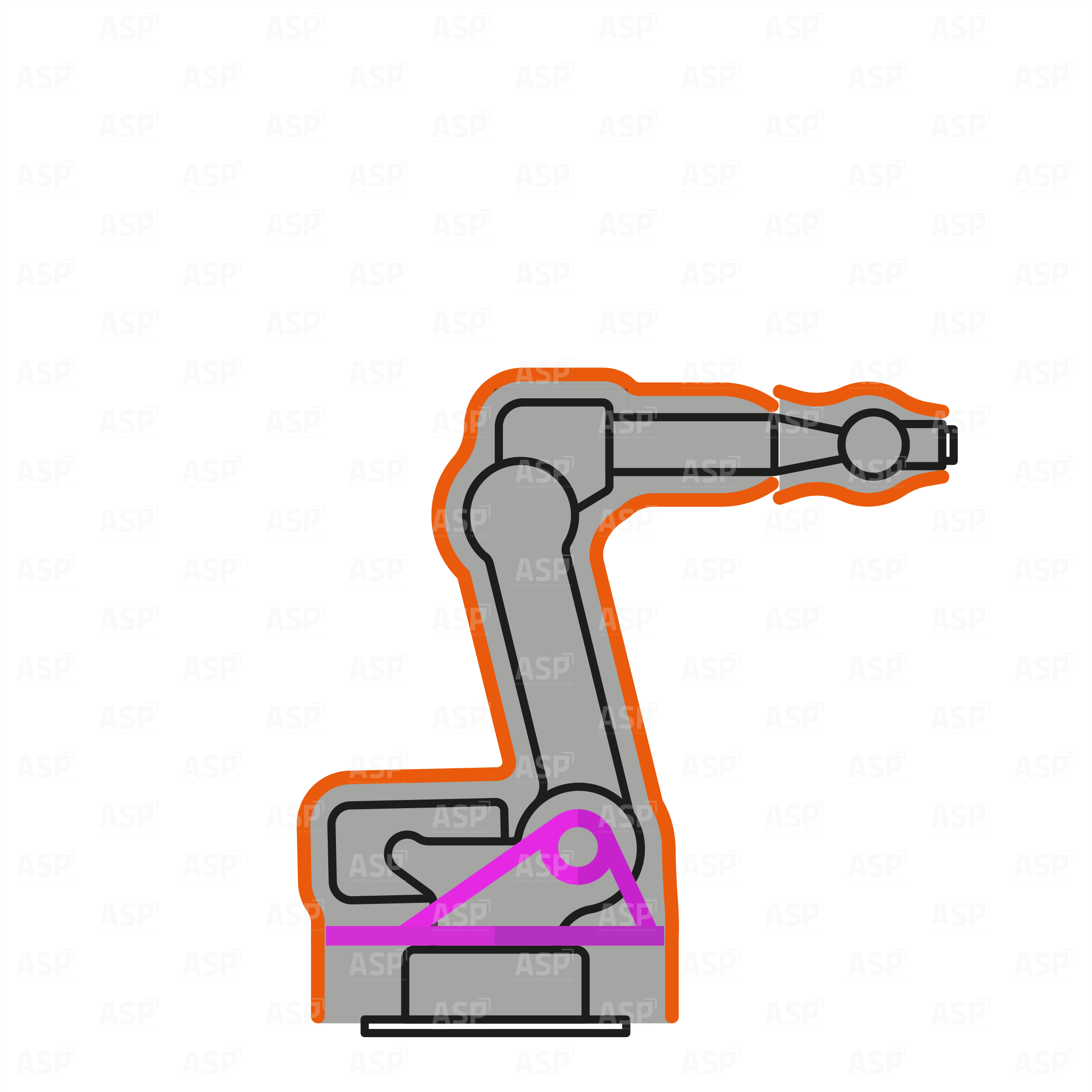

Solution 4: Body cover fixed to Axis 1 hoop + skirt + wrist joint

Interessed by our covers ?

The advantages of ASP

- Protective covers perfectly adapted to aluminum, brass, or magnesium spatter

- Protected seams for optimal seal

- Washable and repairable protection solutions

- Protective covers perfectly adapted to heat and cooling lubricants

- Multiple fabrics available depending on the process

- Fire-resistant protective covers rated M1 if necessary

- Adaptable reinforcements in sensitive areas.

Your constraints:

- Aggressive fluids

- Chip/fluid penetration inside the robot

- Protection of the different robot axes